For Estimators

Fast, accurate, and consistent estimates

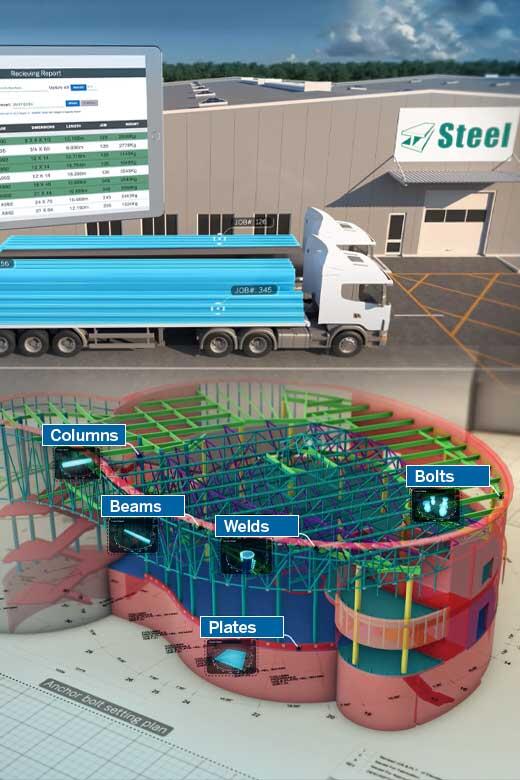

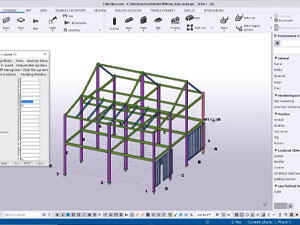

Enjoy efficient model-based estimating workflows or intuitively input data for manual estimates. Quickly create estimates and work with the confidence that costs are covered, and your bid is solid, accurate, and competitive. Make informed and precise estimates with an up-to-date database of supplier pricing and delivery details.

"We know what steel we're using for each job. We know exactly where that's going to go. We can save on the waste; we can reallocate the waste. It will let us know when we're running low. It'll let us know when we need to reorder automatically. It's data that we've never had." - Matt Hastwell, Wareing Buildings

Read more about GMF Industries’ success with model-based estimating